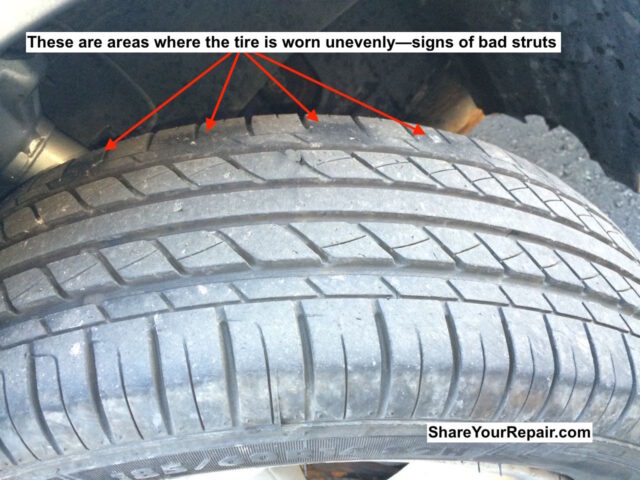

The tires of my 2005 Hyundai Accent were showing “strut wear,” — uneven, lumpy wear, which is a sign that the tires are bouncing off the ground when I hit bumps–a sign of bad struts. Here’s a picture that shows the strut wear on my tires, the dark areas are deep grooves worn into the tire:

The price Midas quoted me for replacement of all four struts, including parts was $1,141!?!!? I was able to buy the four struts for less than $150, so that is like $1,000 in labor! No thank you!! I’m breaking up the front and rear struts into two posts, this is the front strut replacement. For the rear struts see my article here:

1999-2005 Hyundai Accent Rear Strut Replacement

Ok, time for another repair. If you want to save yourself a thousand dollars follow along…

1999-2005 Hyundai Accent Front Strut Replacement

Equipment:

Parts Needed:

- For all 4 struts (springs not included but you will transfer your old springs to the new struts): 7070 – SENSEN Shocks Struts, Full Set, 4 Pieces, NEW, Lifetime Warranty

(these will work on a car with or without anti-lock brakes)

- Front Set: 7070-FS – SENSEN Shocks Struts, Front Pair, 2 Pieces, Lifetime Warranty

- OEM Strut Part Numbers: Rear Right Strut 55360-25650, Rear Left Strut 55350-25650, Right Front (w/ABS, w/sport suspension) 54660-25850, Front Left (w/ABS, w/sport suspension) 54650-25850, Front Left (w/ABS, w/0 sport suspension) 54650-25650, Front Right (w/ABS, w/0 sport suspension) 54660-25750

- WD-40

(for spraying your rusty nuts and bolts ahead of time for easier removal)

- Anti-Seize Compound

(so the bolts come off easier next time)

Tools Needed:

- Hydraulic Jack

- Jack Stands

- Wheel Chocks

- Very good 1/2″ air impact wrench

- Air Compressor

- Lug Wrench

- Phillips Screwdriver

- 12mm, 17mm sockets (1/2-Inch Drive Metric Impact Socket Set

)

- 19mm deep-well socket (1/2-Inch Drive Metric Deep Impact Socket Set

)

- 12mm open-end wrench

- MacPherson Strut Spring Compressor Set

(but most auto parts stores will loan these out for free, with a deposit)

- Small Crescent Wrench

- Large Vice Grip

(for holding spring in place when releasing the spring clamps)

- CLC Pit Crew Gloves

I’m going to change both the front and the rear struts and I’ll start with the rear ones first, here we go… One thing to note is that I’m only going to go over one back strut and one front strut but I may switch back and forth between the right and the left (which are just mirror copies of the others) to give you the best picture of that step.

Typically I would not wear gloves when working on my vehicles but I purchased some CLC Pit Crew Gloves and I have to admit that they really saved my hands:

Step 1: Spray your nuts and bolts with WD-40.

The two main bolts on the lower end of each strut are likely to be stuck fast in place so you want to loosen them up if you can in advance. It may not help at all but it is worth a try. For the front wheels, turn them all the way to the left, like this:

Step 2: Block your back wheels so the vehicle doesn’t roll when you are jacking it up.

Step 3: Break your lug nuts free while the vehicle is still sitting on the ground.

If you jack it up the wheels will want to spin and you don’t want to put all that pressure on the drive shafts, etc.

Step 4: Put the front end of your car up on jack stands.

It is not safe to work on a vehicle that is being held up with a jack. The jack could fail causing the vehicle to come down on top of you. The safe way to work on a car is to block the wheels on the end you are not working on and jack up the other end and place the vehicle down on jack stands.

I didn’t document this step very well with pictures but I can tell you that I jacked up each side individually, placing the jack on the square beam that runs the middle of the vehicle on each side and put a stand under the beam on that side of the vehicle (towards the front of the car). When I jacked up the first side (toward the front of the car) the entire side of the car came off the ground (front and rear) since most of the weight is in the front, but when I jacked up the other side both rear wheels then rested on the ground. In the pictures below in steps 5 and 6 you can see the jack stand in the background…

Step 5: Remove the front wheels.

Keep track of which one goes on which side so you can put them back on the same side.

Step 6: Jack up the wheel assembly to take any pressure off the top nuts.

Step 7: Remove the top nuts from the strut.

They are 12mm. Here is the location of them on the passenger side:

Once you have the nuts removed you can remove the jack from under the wheel.

Step 8: Remove the bolt that attaches the brake line to the strut.

Here I am removing it with a 12mm socket and ratchet. You don’t want to put a bunch of weight on that brake line when the strut is released from the vehicle. These were pretty easy to remove for me:

Here the brake line is free from the strut. I like this design a lot better than the rear struts with the spring clip–this is so much easier:

Step 9: Remove the lower strut nuts and bolts.

Time to get out the biggest impact wrench you have. I didn’t need to hold the bolt steady while I took off the nuts because they are stuck pretty good in there. You may need to put a wrench on the head of the bolt if your struts have been replaced:

The best way I found to remove these bolts was to put the impact wrench on the head of them and pound them out with air:

For one of my front struts I could not get the socket on the head of the bolt to remove it from the strut. In retrospect I wonder if I could have just turned the steering wheel to the right in order to get the end of the tie rod out of the way. I ended up disconnecting the end of the tie rod to give myself room to put the impact wrench on the end of the bolt:

Once I was able to get them spinning they came out easily.

Step 10: Remove the strut and compare with the replacement.

After you get the two lower bolts out carefully remove the strut from the wheel well. Make sure not to allow the strut to drop down on the rubber boot or to damage the brake line.

Step 11: Transfer the old spring to the new strut.

Step 11a: Compress the spring with the set of spring compressors.

Although I’ve never known anyone who has had an accident transferring their springs from an old strut to a new one this is a potentially dangerous step so please use caution. That compressed spring holds a lot of potential energy and if you were to compress it and then drop the assembly and have the spring compressor tool break, it could really hurt you, so proceed with caution.

You will need to attach the two spring compressors on opposite sides and attach them on the spring giving yourself enough room to compress the spring sufficiently so that it will be freed from the strut but not so close to the ends of the strut so that it gets pinched in the process and then you can’t get the spring compressor off once you’ve compressed the spring. I had 3 coils of the spring on the right side and 4 on the left (as seen in the image below, which was from when I changed the rear struts). I’d use your impact wrench to tighten the spring compressors and make sure to keep the two compressors even so the spring doesn’t lean way to one side. Tighten one a bit and then tighten the other one a bit. Here’s what mine looked like when it was when the spring was fully compressed:

You will know you have compressed the spring enough when the strut moves free from the spring on the lower end.

Step 11b: Remove the top nut.

Once you have the spring compressed you can remove the top 19mm nut and remove the strut. The piston of the strut will turn when you are loosening the bolt so I held the piston in place as seen below:

Here the spring is removed:

Step 11c: Transfer the dust guard, spring pad, bump stop, and old spring to the new strut.

Transfer the dust guard, spring pad, and the bump stop to the new strut and then insert the strut into the old spring. There are rubber nipples that stick through the strut on the spring pad but many of them pulled off for me when I was removing them because the rubber was rotted. I didn’t worry about it–you just need to be more careful that the spring pad doesn’t move out of place when you are reinstalling it on the new strut.

Make sure to line up the end of the spring with the step that is formed into the strut so it matches up on both ends. I found that the spring liked to move around so I lined the spring up and then locked it in place on the bottom end with a vice grip so it didn’t move around:

Step 11d: Reinstall the top nut and rubber cap.

Tighten the 19mm nut by hand until you can lock a vice grip on the very end of it and can hold the piston still while you tighten it all the way.

Install the rubber cap after you reinstall the top nut:

Now the new strut is ready to reinstall into the car:

Step 12: Reinstall the strut up into the car.

Carefully feed the lower end of the strut down through past the brake line like this in order to give yourself clearance enough on the top end to slip it into the wheel well:

Step 13: Reinstall the top 12mm nuts.

Step 14: Reinstall the lower bolts, nuts, and brake line bracket bolt.

I lathered up the lower strut bolts with anti-seize before installing them into the strut/wheel knuckle assembly:

After you have inserted the strut bolts, reinstall the brake line bracket bolt:

Then tighten the strut bolts:

Step 15: Reinstall the wheel.

Install the wheel and hand-tighten the lug nuts. Lift the vehicle off the jack stands with the jack and then tighten down the lug nuts when the wheels are resting on the ground.

Now you have saved yourself $500 if you just did two struts and close to $1,000 if you did all four!

Amazon Associate Disclosure: As an Amazon Associate I earn from qualifying purchases. This means if you click on an affiliate link and purchase the item, I will receive an affiliate commission. The price of the item is the same whether it is an affiliate link or not. Regardless, I only recommend products or services I believe will add value to Share Your Repair readers. By using the affiliate links, you are helping support Share Your Repair, and I genuinely appreciate your support.