Background

I’ve had this 9.6 volt Makita cordless drill and flashlight since I graduated from high school and slowly some of the original battery packs have degraded. I have purchased some additional battery packs and was almost ready to throw away some of the original ones that won’t hold a charge and then the itch to repair something overcame me and I decided to tear into this battery and see whether I could replace the cells, rebuild the battery, and breath new life back into it.

How to Disassemble Makita 9.6V NiCad Battery

Equipment Involved:

- Makita 6095DWE 3/8-Inch 9.6 Volt Cordless Keyless Drill

(my drill is not manufactured anymore, they are currently selling this model)

Tools Required:

- Safety Glasses

(these are the ones I’m wearing and I like them)

- Dremel Tool

- Dremel Reinforced Cutting Wheels/Disks

(make sure to get the “reinforced” ones because the other ones are brittle and break very easily)

- Dremel 4486 MultiPro Keyless Chuck

(not necessary but it makes changing bits on your Dremel so much easier and will hold smaller tools too)

- Hacksaw

(if you don’t want to use a Dremel)

- 9.6v Ni-cd 1300mah Battery for Makita 9000 9033 192696-2 632007-4 (Makita Equivalent)

(if you just want to replace the battery)

- Needle Nose Pliers

- Channel Lock Pliers

- Flat Head Screwdriver

- Bench Vice

- Band-Aids

(if you gouge yourself like I did–don’t do that)

Parts Required:

- 1.2 volt NiCad battery cell (physical size of each original cell: 1.625″ long, .86″ in diameter)

- Sub C 2200mAh NiCd 1.2 V Rechargeable Batteries

(replacement cell set)

Step 1: Cut the battery case open

I first tried to pry the battery open with a flat-head screwdriver at the only possible opening, the very end, but the cap must be either glued shut or it is ultrasonically sealed:

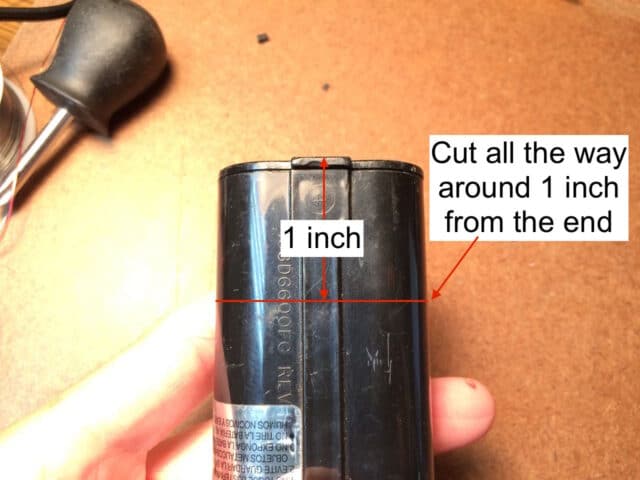

Now that I know what I know I would recommend cutting the case open about an inch from the end of the case and cut as shown below, being careful not to cut into the batteries inside. The batteries are 1.625 inches long so this will put the seam right in the middle of a battery, which will help you remove the old batteries (there’s plenty to grab a hold of) and having a “cap like” piece will aid in re-assembling everything and sealing the case back up when we are done. The original batteries were inside cardboard tubes in my case, which will protect them but if you nick them it won’t matter. Here’s where you should cut the case:

Make sure to wear safety glasses whenever you operate a Dremel tool, this is the pair I wear, and they are pretty comfortable:

When I cut the first battery open I cut along the seam (don’t do this, cut it an inch from the end):

By cutting on the very end you don’t have much to work with when you eventually re-adhere the end cap back on. By cutting it like I suggest above, you have the body of the battery cells supporting the case and you’ll have a better result in the end. Below is what it looked like when I cut it an inch from the end. First I scored a line with my caliper, an inch from the end:

I Dremelled all the way around with a cutting disk:

Step 2: Clean up along the seam where you cut

After you cut the case there will be a burr along the edge that will be in the way of you pulling the battery cells out of the case. Use your fingernail, pocket knife, or screwdriver to clean up the edges where you cut the case–the heat produced by the Dremel cutting wheel will melt the plastic and leave a lip on the edge.

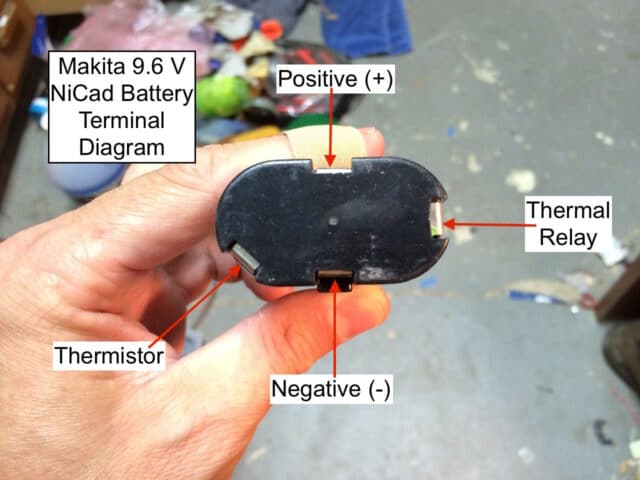

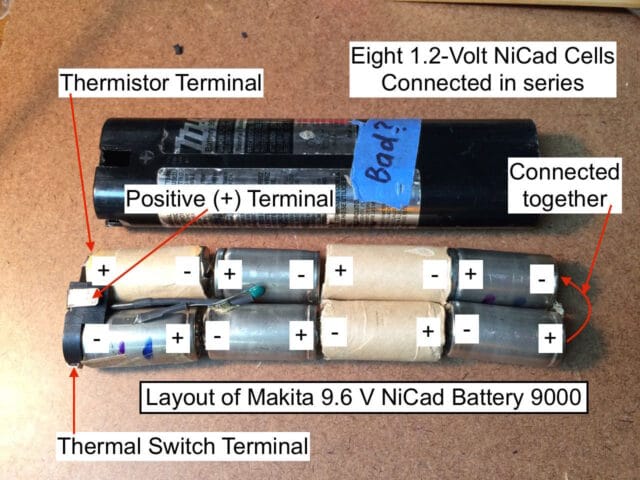

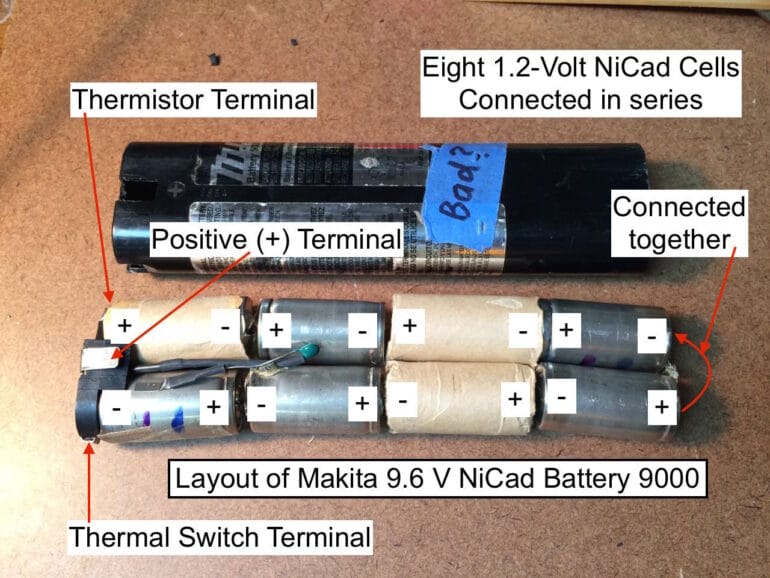

Step 3: Understanding the battery terminals

The first time I took one of these batteries apart I thought that two of the metal connectors of the battery were connected to the external case. Therefore, I thought I needed to bend them straight, thinking they needed to be pulled into the case as I pulled the NiCad cells out the other end. Later I learned this isn’t the case but I wanted to explain why you might see them bent out in subsequent pictures. I did learn what was connected to what and here is a diagram of the battery terminals:

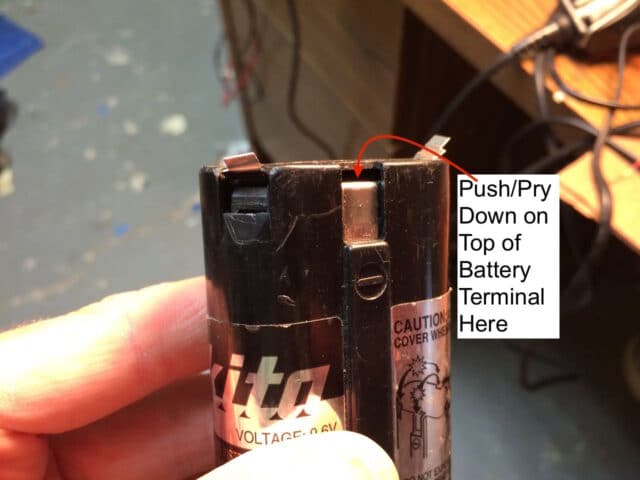

Here you can see what I mistakenly did, DO NOT DO THIS:

Step 4: Push/Pull the cells down out of the case

If you cut the case an inch from the end the battery will slide right out in one piece with ease:

If you cut the case at the very end like I did the first time you will have a different experience… The metal battery terminals will go down with and while the cells pull out so you can push down on them to help force the cells out. Be careful not to pry too much against the plastic case of the battery because the case is not that strong and you’ll break it. Important: Do not short out the positive and negative terminals with your screwdriver. This could happen when the cells begin to push down and your screwdriver can go in one hole and out the other and therefore come into contact with both battery terminals.

Here you can see the cells are beginning to slide down:

If you cut the case where I recommend (an inch from the end) then I believe you will have an easier time pulling the NiCad cells out than I did. I had to use my channel lock pliers and my vice to grab hold of the batteries in order to pull them out. Don’t worry about the batteries pulling apart, where you’ll be left with something like this:

You can tear out the cardboard and then tap the battery pack gently to work the battery cells out. Here I am tapping them on the basement concrete floor:

Here I was able to pull another one out with my channel lock pliers:

Here you can see how the cells pull apart when you pull them out:

After I was able to remove five of the batteries I was able to see the thermistor, the blue ball seen in the picture below:

A word about battery charging and the purpose behind the thermistor

Battery chargers need a way to determine how long to charge a particular battery. NiCad batteries are unique in that their temperature rises as the cell nears a full charge–to 113-122 degrees F (45-50 degrees C). You can read more about this in the Wikipedia article on NiCad Batteries. The thermistor senses this temperature change and tells the charger when to shut off. Here’s a picture of the thermistor, which was glued to the side of the cardboard tube, but I just pealed it off:

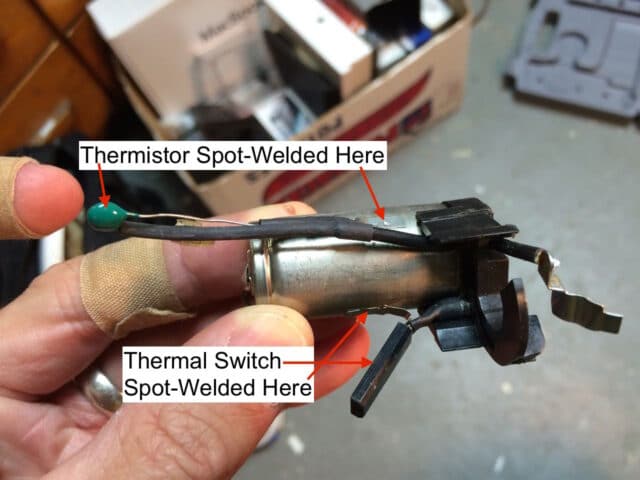

I pulled the last three cells out, broke off the lone one seen above, and you can see the connectors on the end have come with the cells:

A Quick Lesson on the Makita Charging Circuitry

I like to learn about the stuff I take apart and while we’re in here I want to figure out how things are connected. There are two non-power terminals. One non-power terminal is connected to the thermistor, which is spot-welded to the last cell in the series on the negative end. The other non-power terminal is connected to a Klion 4-S 4MM45B-05 Z7J 1 chip and also spot-welded on the same battery:

I was unable to find any information on the Klion 4-S 4MM45B-05 Z7J but based on the other documents that came up when I searched I believe it is some kind of thermal switch. Here are the details of the thermal switch:

A Final Look at The Insides of This Battery:

It was fun disassembling this battery because I got a look at how it is put together and see how the feedback circuitry was connected. Now the next step will be to replace the NiCad cells with new ones. Read how I replaced the cells on the following article:

How to Refurbish a Makita 9.6 V NiCad Battery

Amazon Associate Disclosure: As an Amazon Associate I earn from qualifying purchases. This means if you click on an affiliate link and purchase the item, I will receive an affiliate commission. The price of the item is the same whether it is an affiliate link or not. Regardless, I only recommend products or services I believe will add value to Share Your Repair readers. By using the affiliate links, you are helping support Share Your Repair, and I genuinely appreciate your support.

what was the cost of the new batteries ?

$22 for 15 right now on Amazon.

Hi, When a cell is leaking, but still putting out a good voltage, can it just be cleaned up and re-sealed to continue using it ?

Rich, I believe a leaking cell is a secondary sign that it is bad, either from physical damage or incorrect charging–keeping it sealed will not make it good. I found this article on the built-in vent on NiCad cells.

John, can’t tell you how pleasantly “shocked” I was to find your post! Encountered my old saw last week (maybe it’s older than you?) and battery last week, and wanted to do a project, like yourself, to rejuvenate this neat little saw. The battery has been staring at me, daring me to come up with something. I too like a challenge. My ideal solution would be to convert it from NiCad to AC via an external battery source. I won’t mind using it with a cord. You answered some important questions, like “what’s inside” and what are the two extra terminals for. Not knowing what’s inside, an early thought was to run just make two shallow troughs up the case to accommodate two wires to the + /_ terminals somehow. But you took it all apart!!!! So the wheels are turning in a different direction now. Great stuff – and educational. Need to research DC transformers or power supplies. Out of my knowledge base but will be soon. Thanks much – you never know what pops up on the Web. Great to be indoors now. Not interested in posting comment, just wanted to thank you.

Sounds like a rather low-tech approach, but I guess it mostly worked. Ultimately I had to give up on the DIY approach as I couldn’t reliably rebuild the battery. I just grabbed a new battery on eBay for like $15. Not sure why I didn’t do that in the first place with that small a price tag! I still needed to spend some time refreshing the contacts, but eventually I had the old drill running again.

Older 9000 batteries had only the thermal switch that was used in the manual (push red button to start charging) chargers. It is a simple holding relay circuit that stops when the battery gets hot. The thermister is used in the newer ” smart ” chargers.

Thanks for those details Ken, all I’ve ever had is the older charger with the manual red-button charge start.

An excellent write up! Good simple but complete explanations. I am about to tackle the Makita 9120 9.6 v battery and I may be inspired to follow in your foot steps.

Thanks,

Hugh

I’m in the process of doing the same thing as you, also with an early-90’s Makita 9.6 drill, model# 6093D. This one differs a bit as it does NOT have the 4th contact point for the thermistor. It only has the thermal switch. But I’m wondering if I even need to bother with that, or do you think it’s used to shut off the charger. I just checked and indeed the charger only has 3 contact points.

Brad, I wouldn’t leave it off. How do you know it is a thermal switch and not a thermistor? I wouldn’t leave it off. I believe it HAS to have a thermistor for charging and if you take that off you will ruin your new batteries. I’d retain all the components if I were you.